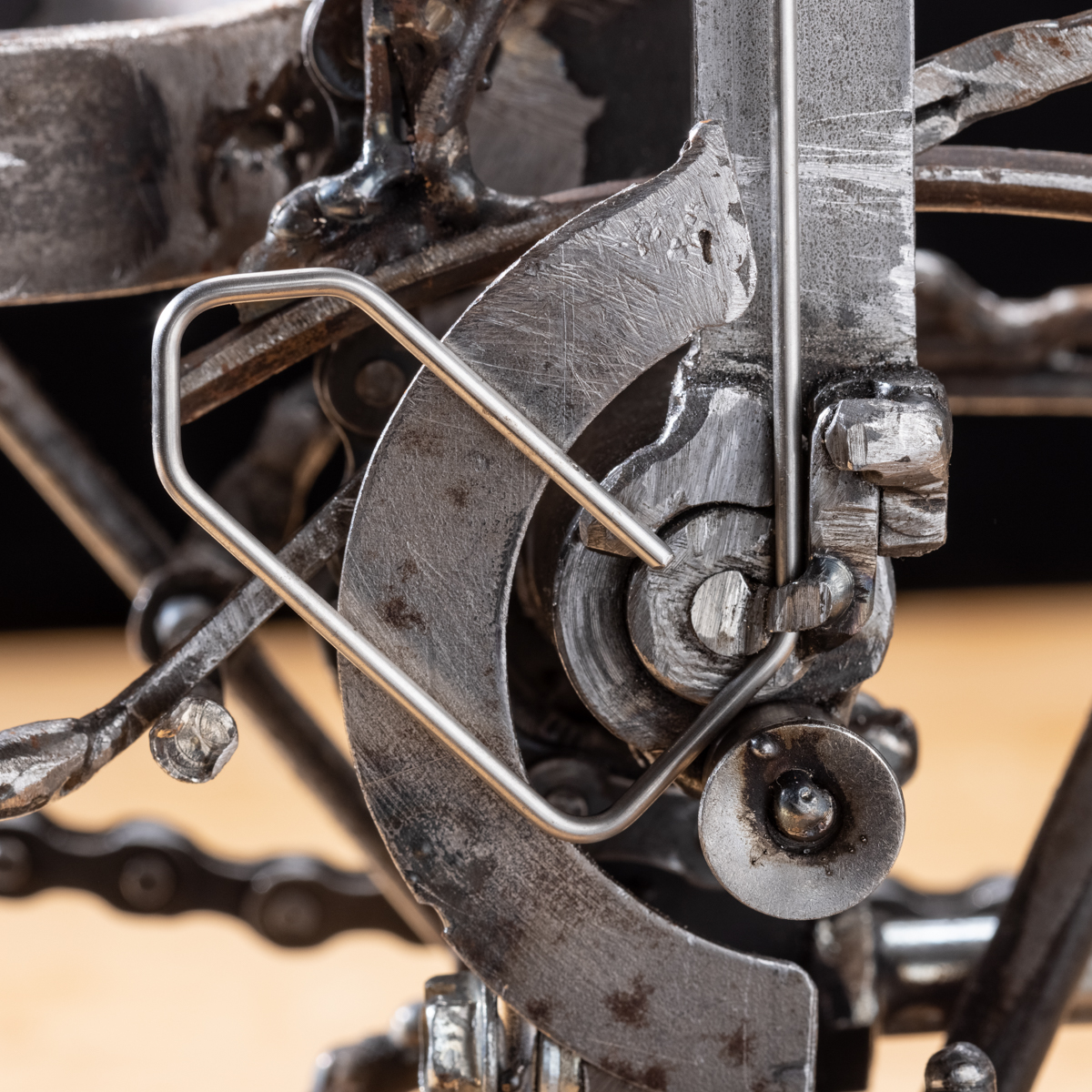

Fechenheim Wire Goods (“Fechenheimer Drahtwaren”)

One day, as a part of my restaurant order pad project, I found myself designing a spiral notebook. So there I was, reshaping wires to enable this practical page-flipping aid.

The ideal raw material for these wires turned out to be bicycle spokes. Old bicycle parts are always lying around my inventor’s workshop anyway. I would often use spokes to make hooks, loops, and even springs.

Then my mind started to wander…or wonder. Dealing with all those pieces of paper, it’s only natural that at some point my thoughts landed on the classic paper clip. But instead of thin wire, it would be forged out of a bicycle spoke. I was so fascinated by this idea, I had to try it out right away.

Due to the dimensions of the spoke wire, the result was a wire clip about 6 cm long, 2 cm wide and with a capacity for up to 7 mm of paper.

Wellspring bicycle spokes

The ideal dimensions for bringing order to my desk and the immeasurably expanded order pad business. But why stop there? The larger-than-life paper clip became a real eye-catcher and it had a downright practical use too, so it was also well suited as a gift!

In short: another project emerged for the disabled people at the workshop where I’m employed. With the right equipment, we would be able to produce these paper clips in larger quantities.

There was no shortage of bicycle spokes, which could be found almost anywhere. It soon proved itself to be a veritable wellspring for further product ideas, as well, such as key rings, small chains or even screw carabiners, which could be made from all parts of the spoke.

We derived the name for the project from the quarter of Frankfurt where the workshop is, “Fechenheimer Drahtwaren” (Fechenheim Wire Goods), including a hint of retro, as it sounds a bit like the name of an old shop. The photos by Matthias Wenger speak for themselves.

Real Artists

To train the staff, I offer a handcraft course at the workshop called “Objects Made of Wire”, teaching the basic skills of metalworking aligned with their skills. We start by completely disassembling the wheels with hand tools. The spokes, usually 2 mm thick, can be sawed into lengths with small saws. The ends of these individual pieces can then be smoothed down with small files. You get a feel for the material by doing this. Those who have gained enough experience can use wire cutters instead of a saw and a crank handle grinder instead of a file. Then, after some instructions, comes the work with bending devices, with which the lengths of wire are bent into shape.

Last but not least, some necessary refinements are taken care of with special pliers. Some real artists can be found for this activity, as well.

I’m very pleased to be able to offer yet another upcycling handcraft activity, in addition to the waiters’ order pad project. Another environmental aspect should be mentioned: aside from possible lighting, no electricity is needed for any of these activities. Besides the products we make in the courses, if any time is left over between our customer orders, my group goes back to making additional wire goods. We sell them to visiting groups or at festivals.

Let’s see if this develops into something more, there are certainly more than enough dedicated workers!